Business Profile

The Washington State Department of Enterprise Services (DES) Print and Mail Services provides a broad range of print, communication and consultation services to state, local and tribal governments, as well as qualified non-profit organizations. DES Print and Mail prints approaching 160 million pieces annually, with an average monthly mail volume of over 3.7 million, using high-speed laser printers and various other production equipment.

Industry

Government, In-Plant

Production Flexibility with Solimar Systems Keeps Customer Communications Flowing

Watch the Case Study Overview

Introduction

Shortly after becoming a state, the State of Washington recognized the need for printed communications and, in 1890, established an official State Printer. Always evolving to meet the needs of the local jurisdictions and residents, the print and mail operation continues to adopt and implement technology to provide timely and cost-effective print communications as part of the state’s Department of Enterprise Services (DES).

Managing an entire state’s printed communications is a challenge under normal circumstances. Adding remote and hybrid work schedules and enhanced safety and security protocols to the mix requires a scalable and flexible print production workflow to keep operations flowing smoothly. Washington State’s Print and Mail Services rose to meet customer needs thanks to its robust IT infrastructure supported by highly-automated processes and workflows that leverage solutions from Solimar Systems, including Rubika, SOLfusion, Solimar Print Director Enterprise (SPDE), and, more recently ReadyPDF.

DES Print and Mail prints approaching 160 million pieces annually, with an average monthly mail volume of over 3.7 million. To keep up with the average and peak demand cycles, the operation uses toner and inkjet digital printing technologies in roll-fed and cut-sheet configurations from two vendors. Adopting inkjet printing technology provided speed and cost advantages but required additional workflow considerations to optimize customer-supplied files, often in PDF format, for the AFP and PostScript output formats used by the two print platforms. Solimar caught up with Michael Zimmerman, the Digital Print and Mail Solutions Architect for the State of Washington, to get an update on how Solimar’s Chemistry™ Platform continues to increase flexibility and improve print operations.

At-A-Glance

Locations

- Tumwater, WA, USA

Business Solution

- Data Stream Conversion

- PDF Optimization

- Document Re-engineering

- Output Management

- Workflow Automation

Solimar Products

- SOLfusion™

- Rubika®

- ReadyPDF® Prepress Server

- Solimar® Print Director™ Enterprise

- Solimar® Indexing Tools

Benefits

- Optimized PDF files and decreased storage requirements with up to 89% file size reduction

- Lowered production costs by 42% by optimizing color applications and transitioning them to B&W for output on high-speed inkjet devices

- Streamlined incoming files through batching, adding barcodes, and address validation via an NCOA integration with BCC Software

- Optimized customer-supplied AFP and PostScript® files for output on toner and inkjet digital printing technologies in roll-fed and cut-sheet configurations

"With ReadyPDF, we cut document prep time and production costs by 45%…"

Michael Zimmerman

Digital Print and Mail Solutions Architect, Washington State Department of Enterprise Services (DES)

PDF Optimization Improves AFP and PostScript

Customer-supplied files often introduce processing challenges based on user design decisions and the application that creates the output file. Since DES Print and Mail uses AFP for one of its print platforms, the work can also take longer to process and create larger file sizes than other formats. After extensive testing, the answer to faster workflow, reduced traffic on the IT network, and lower storage costs and load times for e-presentment, was to optimize the PDF before the final conversion to AFP or PostScript.

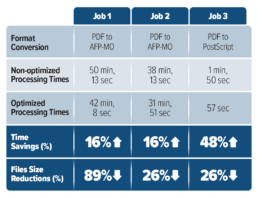

Adding ReadyPDF to the workflow for the existing jobs produced noticeable results. In one example, a repeat job that routinely used over 18,000 fonts for a file with approximately 10,000 pages was reduced to 125 fonts. Three other longstanding jobs showed equally impressive optimizations (See Table).

The reduction in file sizes decreased the storage requirements and allowed DES Print and Mail to delay adding additional storage for archiving.

Zimmerman also notes, “ReadyPDF’s obfuscation features are great!” This less-known feature allows text to be scrambled and images down-sampled to the point where personally identifiable information is no longer readable. The obfuscated files can then be shared with prospects as proof-of-concept examples and with vendors for troubleshooting.

The Chemistry Solution:

SOLfusion™

Automates output production tasks such as external processes & scripts, indexing PDF documents, and executing Rubika® configurations.

Rubika®

Post-composition re-engineering solution to automate manual processes, enable postal savings, add value to documents, and dynamically modify print data.

ReadyPDF® Prepress Server

Optimizes fonts, images, objects, colors and resources to allow PDF files to process more efficiently for production printing, ePresentment and archiving.

Solimar® Print Director™ Enterprise

Output management solution combining integrated connectivity with fast, accurate print stream conversions and job routing & tracking capabilities.

Solimar® Indexing Tools

Powerful PDF indexing tools to design, test and manage indexing templates for data extraction.

"Just flipping our current B&W toner and inkjet volumes would lower the inkjet cost per click by 42%, taking our combined average B&W cost per click to 1 cent across both devices."

Michael Zimmerman

Digital Print and Mail Solutions Architect, Washington State Department of Enterprise Services (DES)

Flexibility in Print Production using ReadyPDF

Transitioning work traditionally printed on toner-based devices to inkjet printers can present challenges from color management and print quality to paper selection and even customer and cultural issues. One scenario that DES Print and Mail experienced was a taxation form that started as two pre-printed duplex master sheets with spot color elements plus multiple pre-printed inserts. As longtime users of Rubika, DES Print and Mail streamlined the incoming files by batching, and invoking further enhancements related to barcodes and cover sheets for operators with the piece counts. Over time, the form was simplified using Rubika to overlay the color shell with the black and white form content. Even with this design improvement, the form continued to be output on a color cut-sheet toner printer to achieve the necessary print quality.

With the addition of ReadyPDF, Zimmerman could optimize the spot color output for inkjet and move the job to a faster and more cost-effective printer. “When it comes to wiring it into the workflow, it was quick because I can reuse objects from workflow to workflow using Solimar’s workflow automation tool SOLfusion.” The results were impressive, with a 45% reduction in costs.

Similar opportunities to transition work from black and white toner to inkjet have been possible because of ReadyPDF. DES Print and Mail prints bills and statements from the state roadway toll system that are supplied in daily batches of 1 to over 100,000 individual PDFs. Each statement uses a common structure: a summary page, activity details, and a payment voucher. Using Rubika, all batches have mailing addresses validated through an NCOA integration with BCC Software that allows for undeliverable pieces to be removed from the workflow before production, providing the state with significant savings by avoiding unnecessary print, insert, and postage costs. In 2021 the volumes increased significantly due to a change in the backend processor, so the department wanted to transition to inkjet to improve production times and costs.

Although the supplied PDFs are color, the files must be prepared for black and white output. Again, the color conversion options of ReadyPDF meant text could be converted to B&W while graphics and images could get a boost using the Gray Dot Gain 10% profile. Ensuring the processed files contained only the black color channel, the overall cost per click decreased. The higher print quality resulting from these optimizations allows DES Print and Mail to move more monochrome work to inkjet. According to Zimmerman, “Just flipping our current B&W toner and inkjet volumes would lower the inkjet cost per click by 42%, taking our combined average B&W cost per click to 1 cent across both devices.”

Although ReadyPDF has become an essential tool, the operation has just started to leverage it within its existing workflows and continues to find additional use cases. As state budgets and staffing logistics continue to change, the optimization and resulting cost savings allow the DES Print and Mail the capability and flexibility to support customers and keep the print communications flowing.