Return to SolimarShorts

SolimarShorts:

Solimar Systems’ Chemistry Platform: Intelligent Automation (IA) Revolutionizes Production Print and Electronic Workflows

In the ever-evolving world of production printing, efficiency and adaptability are paramount. Solimar Systems’ Chemistry™ Platform is a robust solution with roots dating back to 1991. This mature system has been serving customers ranging from small in-plants to some of the largest print centers globally, addressing various challenges in the printing industry.

The Chemistry Platform is designed to help companies boost efficiency, cut costs, and support diverse workflow goals. It seamlessly handles processes from file receipt to hardcopy and electronic delivery channels, making it an indispensable tool for modern print environments.

The Chemistry Platform: A Comprehensive Overview

At its core, the Chemistry platform is a suite of modular products that combine to meet various production print and electronic distribution requirements. It’s designed to address every stage of a typical production print workflow, from the initial receipt of source data to the final delivery of printed materials or electronic documents.

The platform begins at the preflight stage, performing crucial data stream optimizations and job validation testing. This ensures that potential issues are caught and resolved before they can impact production. The Chemistry platform moves into the enhancement and enrichment phase as the workflow progresses. Here, it undertakes document re-engineering tasks, preparing the output for the rigors of production printing.

Print and output management form another critical component of the Chemistry platform. The system expertly manages the output flow to print devices, ensuring that the right jobs reach the right devices at the right time. Throughout the entire process, the platform provides unparalleled production visibility through its sophisticated dashboard, offering job and piece-level tracking that keeps operators informed and in control.

The platform also includes specialized tools like ReadyPDF® that perform industrial PDF optimizations designed for production environments, ensuring smooth processing, high-quality output, and smaller RGB files for ePresentment.

Embracing the growing importance of digital delivery, the Chemistry platform incorporates both push and pull eDelivery concepts through its advanced archive system. This ensures that documents are securely distributed electronically, complementing the traditional print output.

Key Components of the Chemistry Platform

SOLitrack™ Dashboard

At the heart of the Chemistry platform lies SOLitrack—your Document GPS. SOLitrack has a secure, powerful, skinnable dashboard that provides comprehensive tracking and reporting capabilities. It monitors the receipt and progression of jobs throughout the entire workflow, from initial receipt to final delivery. It seamlessly integrates with all Solimar Chemistry products as well as third-party applications via API, webhooks, and hot folders, providing a unified production process view.

SOLitrack’s capabilities extend far beyond simple tracking. It enables many workflow-related concepts such as smart batching of like work, Service Level Agreements (SLA) views, scheduling, and job tracking down to the piece level. The system offers proof and approval functionality, manual and/or automated print distribution and management, and alert notifications for both successes and issues during production.

One of SOLitrack’s standout features is its ability to track the progression of jobs before and during print (including printer status, color, and media information via JDF) and through finishing and mailing. Its open API and utility support integration with external systems and processes, allowing for pushing information to SOLitrack or pulling information from it to feed applications in other areas of the workflow.

The SOLitrack web interface can be run on a desktop, large screen, or mobile device. It allows users to view job information, perform proofs and approvals, release jobs for processing, see device status, and manage alerts and notifications. SOLitrack can even help operations monitor SLA schedules, keeping tabs on production activity and what work is due, past due, or complete.

Solimar® Print Director™ Enterprise (SPDE) and iCONVERT™

File conversion and optimization are crucial in today’s diverse print environments. This is where SPDE, aka Speedy, and iCONVERT come into play. These components handle the critical task of converting various input formats to PDF, which serves as the cornerstone format for the Chemistry platform.

These tools convert a wide range of input files, including AFP, IPDS, LCDS/Metacode, PCL, PDF, PostScript®, and VIPP®, into PDF to support downstream processes. The transforms maintain the fidelity and finishing information of the files as they are converted to PDF and are designed for high-volume production environments. Speedy can also create other output formats, including IPDS and PostScript, for legacy and network printing requirements.

But conversion is just the beginning. These tools also optimize PDF files for better performance and smaller sizes, a crucial consideration in high-volume print environments. They can also detect problematic PDF files before they enter production, preventing potential bottlenecks or errors downstream.

ReadyPDF® Prepress Server

ReadyPDF is a specialized component of the Chemistry platform designed to address the unique challenges PDF files pose in production print environments. As PDF has become the main print stream for many environments, issues with poorly created PDF files have become more prevalent. ReadyPDF is the solution to these challenges.

Key features and benefits of ReadyPDF include:

- Performance Optimization: ReadyPDF ensures that printers can run at their rated speed, addressing issues where poorly optimized PDFs cause slowdowns in production.

- Error Prevention: It helps prevent job failures by identifying and correcting issues in PDF files that might cause errors during processing or printing.

- Quality Improvement: ReadyPDF can enhance the quality of PDF files, ensuring that the final printed output meets expectations.

- File Size Reduction: ReadyPDF can significantly reduce file sizes by optimizing PDFs. This speeds up printing processes and improves electronic delivery and archiving workflow efficiency.

- Production Readiness: It prepares PDF files for production environments, ensuring they’re optimized for high-volume, high-speed printing scenarios.

- Compatibility: ReadyPDF can handle various PDF inputs, from well-formed files to problematic ones, making it a versatile tool for diverse print environments.

By addressing these critical PDF-related challenges, ReadyPDF is crucial in streamlining workflows, reducing bottlenecks, and ensuring smooth, efficient operations in production print environments.

SPDE (Solimar Print Director Enterprise)

SPDE is the nerve center for job and queue operations within the Chemistry platform. It handles file receipt and distribution via various communication methods, ensuring that jobs can be ingested and sent to multiple systems and devices.

SPDE is used to onboard applications into the Chemistry platform if the input files need to be received from something other than file folders, such as TCP/IP or secure IPP connections. On the outbound side, if files need to be sent to something other than folders, SPDE can drive the output via various communication methods, including JDF, IPDS, and TCP/IP.

One of SPDE’s key strengths is its robust job and queue management capabilities. It provides operators with a user-friendly interface for monitoring production activity and controlling job routing. This level of control allows print shops to optimize their workflows and ensure that jobs are processed efficiently.

SPDE also offers additional workflow functionality, such as manually and automatically controlling the routing and scheduling of different jobs. It’s beneficial for handling reprints, allowing for job and page range reprints from a centralized system, which is often more accessible and efficient than returning to the host system.

Rubika®

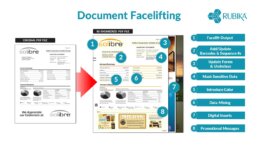

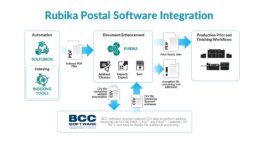

Rubika represents the cutting edge of document enhancement and re-engineering within the Chemistry platform. This powerful tool allows for various manipulations of output files, enabling print shops to modify and optimize documents without returning to the original composition system.

What sets Rubika apart is its intuitive graphical interface for building processing templates. This allows operators to create complex document manipulation workflows without coding skills. With 29 modules available for imposition, barcode updates, and data merging, Rubika provides unparalleled flexibility in document re-engineering.

With nearly 30 modules, Rubika’s capabilities are extensive. It can enhance output by improving content and color elements, updating and adding barcodes for tracking and controlling finishing processes, adding overlay or underlay forms to replicate preprinted stock, adding watermarks, and applying additional content to fill whitespace areas or update messages conditionally.

Moreover, Rubika is crucial in postal processing and supports white paper document factories with inkjet printers. It can export address information for cleansing, sorting, updating, and flagging bad addresses. It also supports digital commingling, which can significantly reduce postal spending by combining multiple application types into a single job for better zip code saturation.

SOLsearcher™ Enterprise (SSE)

As the world increasingly moves towards digital communication, SOLsearcher Enterprise (SSE) stands ready to support eDelivery and archiving needs. SSE provides both push and pull models for electronic document delivery, catering to different user preferences and requirements.

Designed to manage high volumes of transactional and customer-facing documents, SSE is an enterprise-class document archive for storing and retrieving any type of document but offers extensive benefits when archiving PDF files. Its flexible framework can be used in business-to-business (B2B) applications like customer service and case management or business-to-consumer (B2C) applications like retrieving and viewing bank statements and self-service web applications.

One of SSE’s strengths is its powerful search and retrieval capabilities. These are available to end-users and internal staff, facilitating customer service and document management tasks. The system also supports customizable web-based interfaces, allowing organizations to tailor the user experience to their specific needs and branding requirements.

SSE optimizes file storage by archiving entire print runs as single PDF files instead of parsing each record and storing them as separate files. Its storage management also supports hierarchical storage, allowing frequently accessed and near-term documents to be stored on faster media. In contrast, older, less frequently accessed files can be stored on slower, less expensive media. It can also dynamically delete files based on SLA requirements.

Takeaways

Solimar Systems’ Chemistry platform represents a comprehensive solution for the challenges faced by modern production print environments. By offering workflow standardization, reduction in manual processes, centralized processing and control, and support for advanced features like postal optimization and white paper factory workflows, Chemistry empowers print shops to operate more efficiently and effectively.

Specialized tools like ReadyPDF further enhance the platform’s capabilities, addressing specific PDF processing and optimization challenges. This attention to detail across all aspects of the print workflow sets the Chemistry platform apart.

Whether running an in-plant operation or a large-scale print service provider, the Chemistry platform can integrate with your existing systems to provide cost savings, enhanced functionality, and improved workflow efficiencies. As the printing industry evolves, Solimar’s Chemistry platform stands ready to help organizations adapt and thrive in this dynamic landscape.